Understanding HPMC and Its Apps

Hydroxypropyl methylcellulose (HPMC) is usually a semi-artificial polymer derived from cellulose, a Obviously taking place polymer. It really is an essential compound used across various industries, together with prescription drugs, building, cosmetics, and food processing. The importance of HPMC in these sectors highlights its flexible purposes resulting from its special Attributes for example water retention, viscosity raise, and adhesive characteristics. A major HPMC producer performs a crucial job in making certain superior-top quality output and supply for these industries.

What on earth is HPMC?

HPMC is really a modified cellulose ether that possesses several properties useful for various apps. It is actually developed from the chemical modification of cellulose, which requires the introduction of hydroxypropyl groups. This method boosts its solubility in h2o and enables it to serve as a good thickener, emulsifier, and movie-forming agent. HPMC is regarded not only for its performance but in addition for its non-poisonous mother nature, rendering it safe for makes use of while in the food and pharmaceutical industries.

Important Makes use of of Hydroxypropyl Methylcellulose

HPMC finds its application in the myriad of solutions and procedures:

Prescription drugs: Utilized in the formulation of managed-release tablets and capsules, enabling prolonged drug release in the body.

Construction: Functions to be a thickening agent and h2o retainer in cement and plaster compounds, improving upon workability and adhesion.

Food Industry: Serves being an emulsifying and thickening agent in many food stuff products and solutions, maximizing texture and security with no compromising style.

Cosmetics: Utilized in skincare and haircare products for its thickening and stabilizing Attributes.

Great things about HPMC in A variety of Industries

The adoption of HPMC in quite a few sectors gives a number of Advantages:

Flexibility: HPMC is usually formulated with unique Homes tailored to specific apps, offering versatility to brands.

Improved Efficiency: Its ability to strengthen texture and balance is critical for products top quality throughout a variety of sectors.

Security: Remaining a non-poisonous compound, HPMC is approved for use in food and pharmaceutical solutions, making certain purchaser security.

The HPMC Production Procedure Spelled out

Raw Resources and Component Sourcing

The manufacturing of HPMC starts With all the sourcing of Uncooked supplies, generally cellulose obtained from wood pulp or cotton linters. These cellulose resources must be of high quality to ensure the efficacy and protection of the ultimate item.

Essential substances for HPMC manufacturing incorporate:

Cellulose:

Alkali (sodium hydroxide): Allows within the First response to switch the cellulose composition.

Hydropropylic reactants (propylene oxide): Important for introducing hydroxypropyl teams that improve solubility.

These components ought to adhere to stringent high-quality requirements to ensure the last merchandise’s basic safety and usefulness across its apps

The Stage-by-Step Manufacturing Approach

The manufacturing technique of HPMC consists of a number of crucial techniques:

Planning: The cellulose is combined with an alkali Remedy to produce a basic combination. This allows the cellulose to swell, making it extra reactive.

Etherification: Propylene oxide is added on the alkaline cellulose combination, facilitating the etherification system. This step is critical for forming the hydroxypropyl groups.

Neutralization: The reaction mixture is then neutralized to halt the etherification approach, permitting for subsequent drying and formulation.

Drying: The resultant gel is dried into a fantastic powder by spray-drying or roller-drying solutions, yielding the ultimate HPMC product.

Top quality Regulate Measures in HPMC Producing

High quality Management is integral in HPMC producing to fulfill regulatory standards and consumer expectations. Vital measures consist of:

Raw Materials Tests: All incoming components have to undertake screening for purity and excellent.

In-approach Monitoring: Regular checks for the duration of creation make certain that all specifications are adhered to through the entire method.

Closing Merchandise Testing: Extensive testing with the finished merchandise enables producers to verify its consistency pertaining to rheological Attributes, purity, and practical properties.

Marketplace Insights for HPMC Suppliers

Present-day Trends in HPMC Need

The marketplace for HPMC is witnessing progressive advancement, pushed by growing need across a variety of sectors. The subsequent traits characterize The existing landscape:

Design Development: A booming construction market has fueled the need for HPMC for a critical additive in constructing supplies.

Pharmaceutical Innovations: With advancements in drug formulation technologies, the necessity for custom HPMC merchandise customized for unique pharmaceutical applications is increasing.

All-natural Goods Movement: As consumers gravitate towards natural and plant-based mostly solutions, suppliers are striving to satisfy this need by advertising and marketing the organic origin of HPMC.

Competitive Landscape and Pricing Assessment

The aggressive landscape in the HPMC current market is characterized by many critical players, together with recognized multinational businesses and emerging area suppliers. Pricing tactics range based upon generation capability, Uncooked content sourcing, and regional industry dynamics.

In addition, manufacturers must constantly innovate and boost output efficiencies to stay competitive in pricing without having compromising excellent. Knowing market fluctuations and buyer Tastes is vital for helpful positioning.

Problems Faced by HPMC Brands

Despite the booming need for HPMC, brands encounter numerous issues, including:

Raw Product Availability: Fluctuations in The provision of excellent cellulose can affect output steadiness.

Regulatory Compliance: Stringent restrictions bordering chemical production necessitate ongoing compliance endeavours which will strain methods.

Environmental Problems: Given that the force for sustainability rises, manufacturers will have to adapt to eco-welcoming methods, which can necessitate financial investment in greener systems.

Choosing the Proper HPMC Supplier

Components to contemplate When Picking out a Company

Choosing the suitable HPMC provider calls for watchful thing to consider of various things:

Excellent Assurance: Suppliers need to exhibit sturdy quality Handle techniques and ideally have ISO certification.

Customization Choices: The chance to offer tailored HPMC products to suit specialized apps might be an important gain.

Reputation and Experience: A long-standing existence in the market usually displays reliability and experience.

Value of Certification and Compliance

Certifications such as ISO and Very good Producing Apply (GMP) are critical indicators of a supplier’s motivation to quality and safety. Compliance with food stuff and drug safety restrictions ensures that the HPMC created check here doesn't pose a danger to consumers, supplying producers reassurance regarding their offer chain integrity.

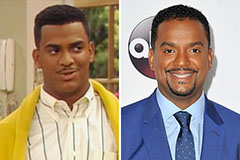

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Tahj Mowry Then & Now!

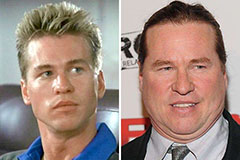

Tahj Mowry Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!